OUR COMBINED CAPABILITIES & SERVICES

Exceeding Your Expectations

PRECISION MACHINING

From prototype to full production and assembly requirements, we specialize in smaller parts with difficult geometries, tight tolerances and fine surface finishes. We work closely with our customers within the Medical Device, Aerospace and Semiconductor industries providing engineering support, DFM, Kanban, dock to stock, along with cost & risk reduction analysis. Materials include: ABS, Acetal, Acrylic, Aluminum, Brass, CoCr, Copper, Derlin, Gold, HDPE, Inconel, Iridium, Nickel, Nitinol, Nylon, Palladium, Platinum, PEEK, PETG, Polycarbonate, Radel, Stainless Steel, Silver, Tantalum, Teflon, Titanium, Tungsten, Udel, UHMWPE, ULTEM, and more.

Multi-axis Swiss machining:

Up to 13-axis micromachining

Quick set-up for maximum cost savings and short lead times

Outside diameters as small as 0.012 inch (0.305 millimeters)

Small hole diameters to 0.006 inch (0.015 millimeters)

Thin wall machining to 0.0015 inch (0.038 millimeters)

Drill and mill perpendicular to axis

Maintains extremely close tolerances up to +/- .0001 inch

Exclusive use of eco-friendly lubricants

Lights-out/Un-manned machining capability

Equipped with multi-bar automatic feeders

CNC Wire & EDM:

Super-close tolerance capabilities of up to .0001 inches

Tapered machining capability of up to 7 degrees

Water submersion (vs. oil)

Uses high-efficiency pallet system for quick setup changes

Runs multiple parts per setup to minimize production time

Lights-out/Un-manned capability

Self-threading wire capability

400mm Horizontal FMS (Flexible Machining System)

Efficient 6-pallet library

5-axis machining capability

3-D Profiling capability

Lights-out/Un-manned machining

Maintains close tolerances of +/- .0002 inches

Customer dedicated tooling/pallet availability

Secure, remote system access

High-RPM spindles

CNC machining:

Micro-machining

Precision CNC milling

CNC turning

Centerless Grinding

Robodrilling

Automatic Saw

Programmable Rotary Tumble Deburring

Laser welding and marking

Assembly

Ultrasonic cleaning:

13 stations

Fully robotic and automated process

Citric passivation as well as Standard Ultrasonic Cleaning

Post Machining Infrastructure:

(Controlled AVL Predominantly NADCAP Certified)

Anodizing

Heat Treat

Welding

Painting

Electro Polish

Supplier performance measured

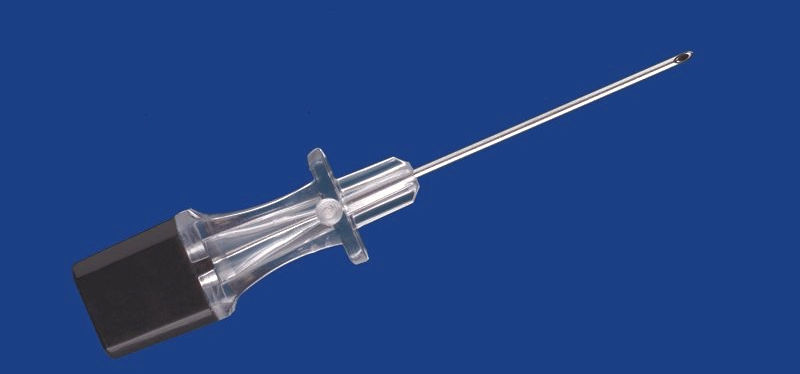

CUSTOM NEEDLES & SURGICAL INSTRUMENTS

Prototyping & design, turn-key products, metal fabrication, plastic fabrication & assembly, packaging & sterilization.

Tube OD/ID Reduction

Tube OD/ID Expansion

Tube Joining

Micro Holes

Slots

Ultrasound Enhancements

CM – Depth Markings

Polishing

Sharpening Custom Geometries

Inspection

Bending

Knurling

Forming

Crimping

Flaring

Heat Treating

Brazing

Cut Lengths

Electro Polishing

Passivation

Piercing

Deburring

Surgical Cleaning

Welding

Ball Ending

Flattening

Sharpness Testing

Tight tolerance molding

Insert molding

Small part molding

Plastic part decorating

Friction reducing coatings

Insulating coatings

Custom molded hubs

Selection of suitable plastic for manufacturing

Complete device assembly

Cannula/Stylet assembly

Bulk Packaging

Indivdual Packaging and Sterilization

Custom printing on pouch or labels

Custom carton sterile packs

Inspection

100% Inspection

Surgical cleaning of parts

Mechanical testing

Sharpness testing

First part Qualifications

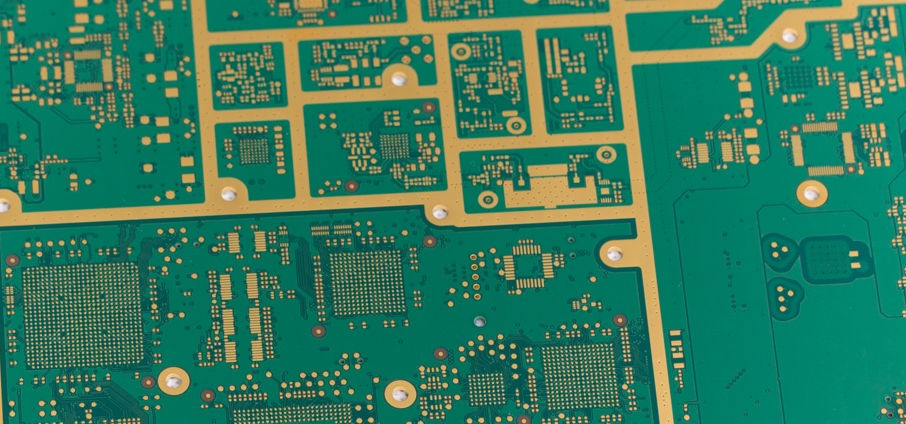

STATE-OF-THE-ART TURNKEY EMS

Global end-to-end electronic manufacturing services with expansive facilities located on the U.S. East Coast, West Coast, Asia and Mexico.

Box Build & Electromechanical:

Offering high-end, box build capabilities which integrate with Cable, PCB assemblies, Magnetics, Metal, and Plastics; individual tests of sub-assemblies for seamless Electro-Mechanical Integration. Our System Engineering teams ensure successful testing, and after an extensive customized End of Line testing procedure, we pack & ship your fully built product.

Printed Circuit Board Assembly:

With more than 100 assembly lines, our PCBA facilities provide highly complex PCB assemblies with very high yield. From quick-turn prototypes to full-scale production, our PCB assembly facilities are future ready providing support on next generation chip mounting capabilities.

Cable & Wire Harness Assembly:

Our cable and wire harness assemblies include industrial as well as milspec applications and the designs can be customized to demanding specifications.

Complex wiring looms as per MIL standards

Flat ribbon cable assembly

RF cable assembly

Custom wire harness

Cable assemblies with overmolding

Board harness

Cable assemblies with potting

Cable assemblies for medical application

Conduit assemblies & harness braiding

Power cables

Magnetics:

Our in-house magnetics capabilities extend to high volume builds, testing and design to custom specifications.

Transformers

Inductors

Solenoids

Chokes

Baluns

Plastics:

Extensive manufacturing capabilities encompass a wide range of high-end plastic devices including:

Plastics tooling

Plastics DFM review

Ultrasonic review

High tonnage capabililites

Materials:

High Performance Plastics

ULTEM (PEI), FPS, NORYL (Mod PPE), PBTGeneral Plastics – ABS

ABS, ABS + 20% GF, ABS _ FRGRGeneral Plastics – PC

PC, PC_ABSGeneral Plastics – Others

NYLON6, NYLON 66, PET, LDPE, HDPE, PE, PVC & TPE

Metal Fabrication:

Providing sophisticated assembly and fabrication for all metal components.

Our expertise includes:

Aerospace metal sub-assemblies

Formed parts

Complex fabrications & assemblies

Machining up to 11 axis

Titanium hot forming – resistance welding

Tool & die manufacturing

Capability to weld and assemble foils

Heat treatment

TIG welding

Brazing

NDT

Finishing process

Industry-leading Engineering Services:

Offering both system design and process engineering services.

Design Engineering: The challenge faced by the design teams across industries is to provide optimal designs at tight budget and timelines. Our in-house design team can work independently or in coordination with our partners’ team to meet your specific design requirements in areas of complete Firmware design, PCB design engineering including Signal Integrity, Thermal and EMI Analysis.

Process Engineering: We will critically re-assess processes and explore faster, smarter and cost-effective ways of doing them.

Full Testing Capabilities:

With extensive in-house quality and testing processes, you can be assured of the highest level product design and manufacturing for all your requirements.

Custom test program design and implementation

In-circuit test and flying probe test

Sub-system assembly and test

Complete system assembly and pack with documentation

Burn-in and accelerated life test

GLOBAL PCB SUPPLY PARTNER

Every technology and service that you will ever need for your PCB fab requirements.

All types of PCB’s including: Double Sided, Multilayer, HDI, Aluminum based, Flex, Rigid-Flex, Teflon and FR4

Quick turn lead-time starting at 3 days

Engineering design support, quality management, supply chain management & quick response to every inquiry

Quarterly audits with every supplier as well as monthly KPI’s

Quality acceptance greater than 99%

Life-of-the-part coverage from prototypes, to pre-production to volume

Daily WIP reports to all customers

Top priority with both pricing and delivery

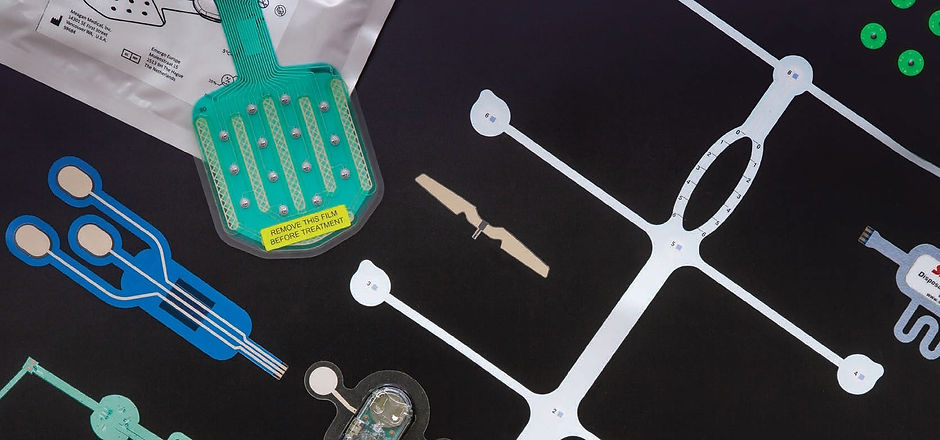

CUSTOM INTERFACE SOLUTIONS

Design and manufacturing of custom human-machine interfaces and medical circuits. (aka: membrane switches, rubber keypads, flexible circuits, graphic overlays and disposable medical circuits

Rubber Keypads

Membrane Switches

Keypad Assemblies

Hybrid Keypads

Standard & Custom Touch Screens

5-wire Resistive Touch Screens

Capacitive Touch Screens

Flexible Circuits

Custom Graphic Overlays

Medical Sensors

Disposable Medical Circuits

Capacitance Switches

SMALL AND MICRO SIZED PLASTIC INJECTION MOLDING

Part design, material selection expertise, lifetime tool warranty, part and product assembly, engineering grade materials from Acetal to Zytel, and everything in between, all at the most competitive pricing.

Evonik & Victrex approved PEEK molding

Metal to plastic conversion specialization

Industry leading Lean molding

ASIM proprietary mold process technology

All class 101 molds with lifetime warranties at the comparable prices to lesser quality molds

Award winning materials expertise including (PEEK / Torlon / Radel / Ultem / Delrin / Lexan)

Rated one of the top 10 molders in the world

CUSTOM GASKETS & PADS

Serving engineers and product designers with high performance gasket and cushioning materials. Each type of application has a unique set of performance characteristics required to ensure proper sealing or cushioning. This Gasket Types section offers insight into common applications for gaskets and pads.

Die cutting of solid and sponge rubber, such as PORON® cellular urethanes, silicone foam, silicone sponge and many solid elastomers and rubber materials

Compression and transfer molding of silicone, fluorosilicone and electrically conductive materials for EMI shielding

Silicone injection molding (LSR) of gaskets, seals and custom components from 10 to 70 durometer Shore A in standard and custom colors

Lamination of pressure sensitive adhesive onto silicone rubber, PORON® cellular urethanes and many other high performance materials. Acrylic adhesive laminated to silicone rubber is one of special capabilities.

Bonding of silicone rubber into layers, conductive coating for ESD grounding and corner splicing of large silicone gaskets and special bonded assemblies

Water jet cutting of sponge and solid rubber gaskets using clean, non-abrasive water jet cutting systems

Silicone Gaskets

Silicone Pads

Molded LSR

Custom Gaskets

Vibration Dampening Pads

Enclosure Gaskets

EMI Gaskets – Conductive Rubber

EMI Gaskets – Combination

Gasket Tape

Custom Gasket Strips

Adhesive Backed Gaskets

Touch Screen Gaskets

Connector Gaskets

Thermal Gap Filler Pads

Custom Conductive Gaskets & Pads

Elastomeric Gaskets